Products

-

Wholesale OEM/ODM Straight Belt Sorting Conveyor Machine Seeds Sorting Belt Conveyor Machine

DWS sorting conveyor system is widely used in logistic , express , e-commerce, factory warehouse…

Fearture:

Sorting speed optional: 1500pcs/h , 2000pcs/h, 2500pcs/h, 3000pcs/h

Rotating angle: 30 /45/60/90/360 degree

Complete sorting system or single sorting machine

Inquiry now for solutions:

Attn: Maria Wang

Mobil/ Wechat: +86-134 8217 6796

WhatsApp: +86-137 6414 5529

Email: mariawang@muxianggroup.com -

Diverter sorter machines for logistic express sorting parcels bags

DWS sorting conveyor system is widely used in logistic , express , e-commerce, factory warehouse…

Fearture:

Sorting speed optional: 1500pcs/h , 2000pcs/h, 2500pcs/h, 3000pcs/h

Rotating angle: 30 /45/60/90/360 degree

Complete sorting system or single sorting machine

Inquiry now for solutions:

Attn: Maria Wang

Mobil/ Wechat: +86-134 8217 6796

WhatsApp: +86-137 6414 5529

Email: mariawang@muxianggroup.com -

2019 wholesale price Work Table Packing Sorting Motorised Belt Conveyor Price for Fruit Picking

DWS sorting conveyor system is widely used in logistic , express , e-commerce, factory warehouse…

Fearture:

Sorting speed optional: 1500pcs/h , 2000pcs/h, 2500pcs/h, 3000pcs/h

Rotating angle: 30 /45/60/90/360 degree

Complete sorting system or single sorting machine

Inquiry now for solutions:

Attn: Maria Wang

Mobil/ Wechat: +86-134 8217 6796

WhatsApp: +86-137 6414 5529

Email: mariawang@muxianggroup.com -

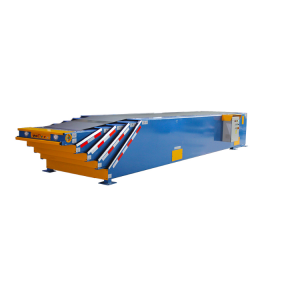

Diverter machine / sorting machine

Sortation Technology Features:

- Widely used by companies of logistic, express , e-commerce, factory warehouse, storage… etc.

- Sorting speed optional : 1000pcs/h , 1500pcs/h , 3000pcs/h, 4500pcs/h …

- Dynamic weighting or quick scanning

- Suppling complete sorting system or signle sorting machines

Inquiry now for solutions:

Attn: Maria Wang

Mobil/ Wechat: +86-134 8217 6796

WhatsApp: +86 137 6414 5529

Email: mariawang@muxianggroup.com

-

Telescopic Conveyor machine for truck loading unloding

Telescopic belt conveyor suitable for bulk Bags boxes cargoes loading and unloading from trucks/ containers. It is widely used in logistic, express,food and baverage, clothing , pharmaceutical industry, other manufacturing factory and warehouse, etc…

It’s optional for below features:

2 / 3 /4 /5 sections

fixed or movable

inclined belt

Hydraulic

High chassis

belt width 600/ 800mm

Bearings:60kg/m

Speed 0-45m / min

Motor: SEW or Nord brand

Belt: Amara Brand

Inquiry now for solutions:

Attn: Maria Wang

Mobil/ Wechat: +86-134 8217 6796

WhatsApp: +86-137 6414 5529

Email: mariawang@muxianggroup.com -

Gravity telescopic belt conveyor / movable conveyor belt machine

Telescopic conveyer suitable for bulk Bags loading and unloading from the trucks. A telescoping conveyor is a flat conveyor that operates on telescopic slider beds. They are popular at receiving and shipping docks where the conveyor is extended into inbound or outbound trailers for unloading or loading. These conveyors used for loading of boxes and cartons in trucks and containers.

Feartures:

Standard type or customized

2/ 3/4/5/sections optional

Bearing: 0-100kg/m

Hydralic for lifting

Belt width: 600/800mm

Inquiry now for solutions:

Attn: Maria Wang

Mobil/ Wechat: +86-134 8217 6796

WhatsApp: +86-137 6414 5529

Email: mariawang@muxianggroup.com -

-

China Shanghai Muxiang belt conveyor / truck loading unloading

Telescopic conveyer suitable for bulk Bags loading and unloading from the trucks. A telescoping conveyor is a flat conveyor that operates on telescopic slider beds. They are popular at receiving and shipping docks where the conveyor is extended into inbound or outbound trailers for unloading or loading. These conveyors used for loading of boxes and cartons in trucks and containers.

Feartures:

Standard type or customized

2/ 3/4/5/sections optional

Bearing: 0-100kg/m

Hydralic for lifting

Belt width: 600/800mm

Inquiry now for solutions:

Attn: Maria Wang

Mobil/ Wechat: +86-134 8217 6796

WhatsApp: +86-137 6414 5529

Email: mariawang@muxianggroup.com -

Telescopic belt conveyor / China manufacturer Shanghai Muxiang conveyors belt

Telescopic conveyer suitable for bulk Bags loading and unloading from the trucks. A telescoping conveyor is a flat conveyor that operates on telescopic slider beds. They are popular at receiving and shipping docks where the conveyor is extended into inbound or outbound trailers for unloading or loading. These conveyors used for loading of boxes and cartons in trucks and containers.

Feartures:

Standard type or customized

2/ 3/4/5/sections optional

Bearing: 0-100kg/m

Hydralic for lifting

Belt width: 600/800mm

Inquiry now for solutions:

Attn: Maria Wang

Mobil/ Wechat: +86-134 8217 6796

WhatsApp: +86-137 6414 5529

Email: mariawang@muxianggroup.com -

High Quality Top Quality Custom Belt Conveyor

The Extendable Belt Conveyor is a telescoping conveyor that extends into the truck trailer as an ergonomic solution for loading and unloading. These conveyors are most commonly found in shipping and receiving areas, warehouses, and other locations where it is necessary to move packages and other items in and out of trucks and shipping containers.Extendable, telescoping conveyors can improve productivity and efficiency at the dock door.

Features:

Length is optional : 2 / 3 / 4 /5 sections

Belt width: 600/800mm

Fixed or movable type

Hydraulic for lifting to different height

Bearing : 0-100kg/m

Speed: adjustable

Direction: two directions

Inquiry now for solutions:

Inquiry now for solutions:

Attn: Maria Wang

Mobil/ Wechat: +86-134 8217 6796

WhatsApp: +86-137 6414 5529

Email: mariawang@muxianggroup.com -

Special Design for Mobile Flexible Belt Conveyor Telescopic Conveyer Combined for Container Truck Warehouse Loading Unloading

Telescopic conveyer suitable for bulk Bags loading and unloading from the trucks. A telescoping conveyor is a flat conveyor that operates on telescopic slider beds. They are popular at receiving and shipping docks where the conveyor is extended into inbound or outbound trailers for unloading or loading. These conveyors used for loading of boxes and cartons in trucks and containers.

Feartures:

Standard type or customized

2/ 3/4/5/sections optional

Bearing: 0-100kg/m

Hydralic for lifting

Belt width: 600/800mm

Inquiry now for solutions:

Attn: Maria Wang

Mobil/ Wechat: +86-134 8217 6796

WhatsApp: +86-137 6414 5529

Email: mariawang@muxianggroup.com -

Telescopic belt conveyor for boxes cargoes loading unloding truck / container

Telescopic belt conveyor suitable for bulk Bags boxes cargoes loading and unloading from trucks/ containers. It is widely used in logistic, express,food and baverage, clothing , pharmaceutical industry, other manufacturing factory and warehouse, etc…

It’s optional for below features:

2 / 3 /4 /5 sections

fixed or movable

inclined belt

Hydraulic

High chassis

belt width 600/ 800mm

Bearings:60kg/m

Speed 0-45m / min

Motor: SEW or Nord brand

Belt: Amara Brand

Inquiry now for solutions:

Attn: Maria Wang

Mobil/ Wechat: +86-134 8217 6796

WhatsApp: +86-137 6414 5529

Email: mariawang@muxianggroup.com -

Vertical lifting conveyor / C/ Z /E type lifter

VRC’s Overview

- Standard weight capacity up to 100kg, 500kg, 1000kg, 1500kg,2000kg, 2500kg, 3000kg

- Unlimited, continuous cycles

- Adjustable lift speed

- Unlimited carriage size

- Unlimited vertical rise

- Indoor or outdoor use

- Lifetime structural warranty

Inquiry now for solutions:

Attn: Maria Wang

Mobil/ Wechat: +86-134 8217 6796

WhatsApp: +86 137 6414 5529

Email: mariawang@muxianggroup.com

Website: www.muxiangmachine.com

Company: Shanghai muxiang automation company. Ltd.

Add: No.1588.Huazhi Road. Huaxin Industrial Park,Qingpu District,Shanghai,China

-

Continuous vertical elevator conveyor lifter 50kg 100kg 500kg

-

Continuous vertical elevator conveyor features:

- Z-type, C-type, and E-type according to the direction of inlet and outlet .

- Speed: customized

- Bearing: 50kg , 100kg, 500kg

Inquiry now with below information:

Attn: Maria Wang

Mobil/ Wechat: +86-134 8217 6796

WhatsApp: +86-137 6414 5529

Email: mariawang@muxianggroup.com -

-

Factory wholesale China Painting Line Chain Overhead Track Chain Conveyor Hanger for Powder Coating Line Conveyor Chain

The Extendable Belt Conveyor is a telescoping conveyor that extends into the truck trailer as an ergonomic solution for loading and unloading. These conveyors are most commonly found in shipping and receiving areas, warehouses, and other locations where it is necessary to move packages and other items in and out of trucks and shipping containers.Extendable, telescoping conveyors can improve productivity and efficiency at the dock door.

-

Factory Customized China Motorized Flexible Powered / Gravity Expandable Roller Conveyor

MUXIANG Floating garbage collector equipment, the main function is to capture floating garbage, separate floating garbage and sewage, and automatically put garbage on shore for bucketing. The principle is to use the high-flow suction formed by the swirling device to force the floating garbage to gather in the direction of the collection bucket. The filter screens of the inner and outer barrels are used to separate the garbage and the water and capture the garbage. The electric lift is used to automatically send the garbage to the top of the pool and automatically dump it into the garbage can, thereby completing the collection of floating garbage.

Advanced technology, leading technology, efficient capture, ensuring compliance

Automatic control, energy saving and noise reduction, simple management, convenient operation and maintenance

High quality, controllable area, low cost, and thoughtful after-sales.

-

ODM Factory China Tapered Idler, Steel Screw Idler, Rubber Coated Idler Roller

The customer satisfaction is our primary target. We uphold a consistent level of professionalism, quality, credibility and service for ODM Factory China Tapered Idler, Steel Screw Idler, Rubber Coated Idler Roller, You would not have any communication problem with us. We sincerely welcome customers all over the world to contact us for business cooperation. The customer satisfaction is our primary target. We uphold a consistent level of professionalism, quality, credibility and service for Chi... -

Good User Reputation for China Customized Belt Conveyor Buffer Roller Rubber Covered Roller Rubber Roller Groove Type Support

Horizontal spiral ribbon mixer is composed of spiral ribbon rotating parts;

The outer spiral gathers materials from both sides to the center,

The inner spiral conveys materials from the center to both sides to form convective mixing. The spiral ribbon mixer has a good effect on the mixing of viscous or cohesive powders and granules.

-

Top Grade China SPD Belt Rollers Conveyor for Bulk Material Handling Mining/Port/Cement

The Extendable Belt Conveyor is a telescoping conveyor that extends into the truck trailer as an ergonomic solution for loading and unloading. These conveyors are most commonly found in shipping and receiving areas, warehouses, and other locations where it is necessary to move packages and other items in and out of trucks and shipping containers.Extendable, telescoping conveyors can improve productivity and efficiency at the dock door.

-

Factory Free sample China Food Industry Small Powder Screw Feeder/Conveyor Machine

Electric wheels sorting machine conveyor used in logistic dividing bag,wheels sorting machine is an equipment used for belt conveyor system or roller conveyor system. The characteristics of this design is to track conveyed goods accurately and stably as well as set sorting positions at any position along both sides of conveyor lines conveniently to satisfy customers with different sorting requirements.

-

Manufacturing Companies for High Quality 90 Degree Curve Belt Conveyor Systemassembly Line

Horizontal spiral ribbon mixer is composed of spiral ribbon rotating parts;

The outer spiral gathers materials from both sides to the center,

The inner spiral conveys materials from the center to both sides to form convective mixing. The spiral ribbon mixer has a good effect on the mixing of viscous or cohesive powders and granules.

-

factory Outlets for Ceramic Ball Bearing 608 626 6000 Zro2 Si3n4 Hybrid Bearing

Roller conveyors are a form of conveyor belt that utilizes rollers – evenly-spaced rotating cylinders – to allow objects to skate across its surface. They move material from one place to another destination, and often leverage gravity or implement small motors to do so.

-

Top Quality Water Weed Harvester Garbage Collection Boat in China

MUXIANG Floating garbage collector equipment, the main function is to capture floating garbage, separate floating garbage and sewage, and automatically put garbage on shore for bucketing. The principle is to use the high-flow suction formed by the swirling device to force the floating garbage to gather in the direction of the collection bucket. The filter screens of the inner and outer barrels are used to separate the garbage and the water and capture the garbage. The electric lift is used to automatically send the garbage to the top of the pool and automatically dump it into the garbage can, thereby completing the collection of floating garbage.

Advanced technology, leading technology, efficient capture, ensuring compliance

Automatic control, energy saving and noise reduction, simple management, convenient operation and maintenance

High quality, controllable area, low cost, and thoughtful after-sales.

-

New Delivery for 201 Stainless Steel Gravity Man up Telescopice Scalable Belt Conveyor for Loading to Vessel

Horizontal spiral ribbon mixer is composed of spiral ribbon rotating parts;

The outer spiral gathers materials from both sides to the center,

The inner spiral conveys materials from the center to both sides to form convective mixing. The spiral ribbon mixer has a good effect on the mixing of viscous or cohesive powders and granules.

-

China wholesale Dismountable Mobile SUS304 Tube Conveyor Roller System for Logistics Distribution

With this motto in mind, we’ve come to be one of quite possibly the most technologically innovative, cost-efficient, and price-competitive manufacturers for China wholesale Dismountable Mobile SUS304 Tube Conveyor Roller System for Logistics Distribution, Top quality and competitive rates make our products and solutions appreciate a higher name all around the word. With this motto in mind, we’ve come to be one of quite possibly the most technologically innovative, cost-efficient, ... -

MX-2A/2B Automatic Filling Machine

Suitable for jar tin

50L side opening hopper,easey to clean

Touch screen Display 2 language,easy to operate

Position screw,connect with the filling machine,make it automatic and faster

Electric control,we use famous brand,steady and easy to get when it is urgent

Servo motor drive the auger which was processing with lathe

-

MX-3AL/3BL Automatic Vertical Bag Packaging Machine

This is vertical form fill and seal machines which are very space-saving, designed for high performance (output) with reproducible sealing. All machines are fully automatic and designed in the Two-Mode-Tec design and operate intermittently and/or continuously. The design of the formats allows the production of tubular bags without and with gusset, block bottom bags and StabilPack bags, also tetrahedron bags or spherical bags. The wide variety of packaging shapes also requires individual forma... -

Screw feeder

230L Round/Square hopper,easy to clean

Using double motors:feeding/vibrating motor,separately controlled.Double chint reverses switch,control the conveying and unloading of materials,separately controlled

conveyor height and tube diameter can be custom by your require

Product hopper is adjustable,avoid product blocking,suitable for different material

Hopper can sepreate from the tube,easy assemmbly

Special anti-dust design to protect bearing from dust

Auger can be pull out for washing,very easy to clean -

MX-1C1 Semi-automatic big bag Auger filing machine

Filling Range:10~50kg

Filling Method:Double screw,Double door

Measurement Method:Gross Weight

Capacity: ≤3bag/min

Filling Capacity: ≤±0.2%

Power:380V50~60HZ/3.9kw(Exclude air supply)

Pressure/Air Consumption:6~8kg/cm2/0.2m3/min

Total Weight/Overall Size:400kg/4000*1200*2400mm

-

Floating garbage collection equipment

MUXIANG Floating garbage collector equipment, the main function is to capture floating garbage, separate floating garbage and sewage, and automatically put garbage on shore for bucketing. The principle is to use the high-flow suction formed by the swirling device to force the floating garbage to gather in the direction of the collection bucket. The filter screens of the inner and outer barrels are used to separate the garbage and the water and capture the garbage. The electric lift is used to automatically send the garbage to the top of the pool and automatically dump it into the garbage can, thereby completing the collection of floating garbage.

Advanced technology, leading technology, efficient capture, ensuring compliance

Automatic control, energy saving and noise reduction, simple management, convenient operation and maintenance

High quality, controllable area, low cost, and thoughtful after-sales.

-

Electric wheels sorting machine conveyor

Electric wheels sorting machine conveyor used in logistic dividing bag,wheels sorting machine is an equipment used for belt conveyor system or roller conveyor system. The characteristics of this design is to track conveyed goods accurately and stably as well as set sorting positions at any position along both sides of conveyor lines conveniently to satisfy customers with different sorting requirements.

Inquiry now for solutions:

Attn: Maria Wang

Mobil/ Wechat: +86-134 8217 6796

WhatsApp: +86 137 6414 5529

Email: mariawang@muxianggroup.com

Website: www.muxiangmachine.com

Company: Shanghai muxiang automation company. Ltd.

Add: No.1588.Huazhi Road. Huaxin Industrial Park,Qingpu District,Shanghai,China

-

Removable Cableless Battery Telescopic Conveyor (3 Sections)

Warranty : One year full warranty

-

Turning Conveyor

Turning belt Conveyor is a kind of conveyors of belt conveyors ,belt conveyors are most commonly used in transportation of bulk materials (grain, salt, coal, ore, sand, etc.). Belt conveyor systems consist of two or more pulleys. An endless loop of carrying medium—the conveyor belt— rotates about them.

-

DWS machine

Belt conveyors are most commonly used in transportation of bulk materials (grain, salt, coal, ore, sand, etc.). Belt conveyor systems consist of two or more pulleys. An endless loop of carrying medium—the conveyor belt— rotates about them.

-

High Chassis Telescopic Belt Conveyor (Motorized Movement type)

Warranty : One year full warranty

-

Telescopic belt conveyor for loading&unloading container

The Extendable Belt Conveyor is a telescoping conveyor that extends into the truck trailer as an ergonomic solution for loading and unloading. These conveyors are most commonly found in shipping and receiving areas, warehouses, and other locations where it is necessary to move packages and other items in and out of trucks and shipping containers.Extendable, telescoping conveyors can improve productivity and efficiency at the dock door.

-

Stainless steel roller conveyor

Roller conveyors are a form of conveyor belt that utilizes rollers – evenly-spaced rotating cylinders – to allow objects to skate across its surface. They move material from one place to another destination, and often leverage gravity or implement small motors to do so.

-

Assembly lines – roller conveyor

Shanghai muxiang assembly lines : roller production line, plate chain production line, double speed chain production line, drying channel assembly line, spraying assembly line, suspension chain assembly line, belt assembly line, plug-in assembly line, aging assembly line, logistics transportation assembly line, non-standard supporting assembly line, manipulator, workbench, turning machine and other automatic assembly line equipment and related accessories. Shanghai Muxiang mainly provides aut... -

Roller conveyor / flexible gravity roller conveyors

Roller conveyor featurers:

- Length and width can be customized as request.

- Carbon steel or stainless steel is optional

- Gravity or light is optional

- Extendable or fixed type as request

- Powered or unpowered

Inquiry now for solutions:

Attn: Maria Wang

Mobil/ Wechat: +86-134 8217 6796

WhatsApp: +86 137 6414 5529

Email: mariawang@muxianggroup.com

Website: www.muxiangmachine.com

Company: Shanghai muxiang automation company. Ltd.

Add: No.1588.Huazhi Road. Huaxin Industrial Park,Qingpu District,Shanghai,China

-

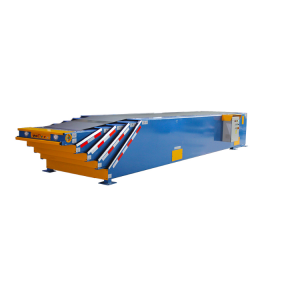

Heavy duty Telescopic belt Conveyor for loading unloading cargoes from trucks / containers

The Extendable Belt Conveyor is a telescoping conveyor that extends into the truck trailer as an ergonomic solution for loading and unloading. These conveyors are most commonly found in shipping and receiving areas, warehouses, and other locations where it is necessary to move packages and other items in and out of trucks and shipping containers.Extendable, telescoping conveyors can improve productivity and efficiency at the dock door.

-

Professional manufacturer of Loading unloading conveyor

Telescopic belt conveyor suitable for bulk Bags boxes cargoes loading and unloading from trucks/ containers. It is widely used in logistic, express,food and baverage, clothing , pharmaceutical industry, other manufacturing factory and warehouse, etc…

It’s optional for below features:

2 / 3 /4 /5 sections

fixed or movable

inclined belt

Hydraulic

High chassis

belt width 600/ 800mm

Bearings:60kg/m

Speed 0-45m / min

Motor: SEW or Nord brand

Belt: Amara Brand

-

Telescopic belt conveyor high chassis movable conveyor belt

☆ Base section A= 6m, extension section B=12m,

☆ H2 height: 800mm

☆ H1 height: 1700mm

☆ Tail L: 4000mm

☆ Belt: 3mm black PVK belt, width 800mm

☆ Frame: 6mm thickness carbon steel Laser, CNC bending

☆ Running speed: 10-35m/minute (adjustable with Schneider frequency converter)

☆ Belt running direction: Bi-directional (Forward& Reverse)

☆ Movement way: motorized movement with battery system

☆ Battery capacity: Continuously move 3 hours

☆ Belt driven: 3.0KW SEW brand

☆ Telescopic motor: 0.75KW SEW

-

Telescopic Belt Conveyor

Telescopic belt conveyor suitable for bulk Bags boxes cargoes loading and unloading from trucks/ containers. It is widely used in logistic, express,food and baverage, clothing , pharmaceutical industry, other manufacturing factory and warehouse, etc…

It’s optional for below features:

2 / 3 /4 /5 sections

fixed or movable

inclined belt

Hydraulic

High chassis

belt width 600/ 800mm

Bearings:60kg/m

Speed 0-45m / min

Motor: SEW or Nord brand

Belt: Amara Brand

-

Nail weighing and automatic arrangement of packing machine

Nail weighing and automatic arrangement of packing machine

1. Description of the packaging equipment

Equipment function requirements: A. Measure the materials through weighing, and then complete the automatic packing through the packing machine

B. Can complete the work of automatic feeding, weighing, arrangement, packing and checking of nails.

C. Can quickly change varieties;

2、 technical description:

A、 Vibration bin: manually pour the product into the bin, automatically complete the vibration feeding to the elevator;

B、 Hoist: the hoist is to give the electronic weighing lifting product to meet the weighing requirements;

C、 Electronic said: is a single bucket electronic, electronic said feeding is horizontal conveyor belt to electronic feeding, conveyor with three speed control, if the target weight is 20 kg, the first speed is fast feeding, the second speed is medium speed feeding, the third speed is slow feeding, finally close to the target weight will stop feeding, this can ensure the feeding accuracy;

D、 Staking machine: adjust the distance according to the length of the nail. Let the nail come down automatically neatly down the box; then the box comes down and the cylinder rolls out.

E、 Check the weight: can automatically detect whether the weight of the installed box is qualified.

A: Packaging speed: about 2-4 bags / minute; specifically see the weighing specifications;

B: Number of labor required: save labor to the maximum extent, complete the production of feeding, weighing, filling, counting, checking, finished product transportation and other links;

C: Change products: convenient to switch materials, empty the bin and replace directly without adjusting the machine; set the production target weight on the computer screen;

3. Specific parameters of weighing and counting automatic box-packing machine

project parameter Production capacity (box / points) 2-4 cases / min (depending on actual packaging) Measurement range Depending on the electronic measurement range gas consumption 0.8Mpa 300L/min Total power of equipment 10KW Equipment voltage 380V contour size of the unit Length 7600mm * width 5000mm * height 2800mm Length of applicable products 20mm-200mm -

Pump Station Grating

Pump Station Grating is suitable for Tree branches, leaves, weeds, household garbage, etc.), and then they are fished onto the bridge deck by rotary tooth rake, and transported away by belt conveyor or other means,

Prevent the sewage from entering the diversion channel and ensure the smooth operation of the unit or other equipment and structures. The rotary trash remover has simple structure, good rigidity

Stable operation, simple operation, good cleaning effect, high efficiency, low energy consumption, and long service life

-

New Arrival China Gold Mining Equipments Mineral Conveying Equipment Rubber Transmission Roller Belt Conveyor for Sand

Turning belt Conveyor is a kind of conveyors of belt conveyors ,belt conveyors are most commonly used in transportation of bulk materials (grain, salt, coal, ore, sand, etc.). Belt conveyor systems consist of two or more pulleys. An endless loop of carrying medium—the conveyor belt— rotates about them.

-

New Arrival China Factory Directly Supply Steel Gravity Skate Wheel Telescopic Roller Conveyor Price with Low Price

Roller conveyors are a form of conveyor belt that utilizes rollers – evenly-spaced rotating cylinders – to allow objects to skate across its surface. They move material from one place to another destination, and often leverage gravity or implement small motors to do so.

-

China OEM Polyurethane Coated Steel Gravity Roller Helical Spiral Elevetor Conveyor for Cardboard Boxes Plate

MUXIANG Floating garbage collector equipment, the main function is to capture floating garbage, separate floating garbage and sewage, and automatically put garbage on shore for bucketing. The principle is to use the high-flow suction formed by the swirling device to force the floating garbage to gather in the direction of the collection bucket. The filter screens of the inner and outer barrels are used to separate the garbage and the water and capture the garbage. The electric lift is used to automatically send the garbage to the top of the pool and automatically dump it into the garbage can, thereby completing the collection of floating garbage.

Advanced technology, leading technology, efficient capture, ensuring compliance

Automatic control, energy saving and noise reduction, simple management, convenient operation and maintenance

High quality, controllable area, low cost, and thoughtful after-sales.

-

OEM/ODM Factory China Precision Machined Brass Linear Guide Bushing Screw, Trapezoidal Lead Screw

A screw conveyor or auger conveyor is a mechanism that uses a rotating helical screw blade, called a “flighting”, usually within a tube, to move liquid or granular materials. They are used in many bulk-handling industries. Screw conveyors in modern industry are often used horizontally or at a slight incline as an efficient way to move semi-solid materials, including food waste, wood chips, aggregates, cereal grains, animal feed, boiler ash, meat, and bone meal, municipal solid waste, and many others.

-

Factory best selling China Good Quality for Conveying Food Industry Hairise1500 Flat Top Modular Belt

Roller conveyors are a form of conveyor belt that utilizes rollers – evenly-spaced rotating cylinders – to allow objects to skate across its surface. They move material from one place to another destination, and often leverage gravity or implement small motors to do so.

-

Quality Inspection for China High Durability Quiet Operation Belt Conveyor Sleeve Roller

Roller conveyors are a form of conveyor belt that utilizes rollers – evenly-spaced rotating cylinders – to allow objects to skate across its surface. They move material from one place to another destination, and often leverage gravity or implement small motors to do so.

-

Wholesale Price China China Yg-2000 Type Belt Conveyor Return Rubber Ring Roller

Turning belt Conveyor is a kind of conveyors of belt conveyors ,belt conveyors are most commonly used in transportation of bulk materials (grain, salt, coal, ore, sand, etc.). Belt conveyor systems consist of two or more pulleys. An endless loop of carrying medium—the conveyor belt— rotates about them.

-

Factory Supply China Plastic Slat Spiral Gravity Roller Conveyor Elevator for Lifting Carton Box

The non-gravity double-shaft paddle mixer has the characteristics of strong, high efficiency, short mixing time, design mixing time of 1-3 minutes, 1:1000 distribution ratio uniformity is greater than 95%, the two mixing shafts in the horizontal cylinder rotate in opposite directions at the same speed , The blades arranged at a special angle on the shaft ensure that the material is sprayed in the radial, circumferential and axial directions at the same time, forming a compound compound cycle, and achieving uniform mixing in a short time.

-

2019 New Style China Small Flexible Plastic Specifications Jual Biaxial Auger Screw Conveyor Feeder Machine

The Extendable Belt Conveyor is a telescoping conveyor that extends into the truck trailer as an ergonomic solution for loading and unloading. These conveyors are most commonly found in shipping and receiving areas, warehouses, and other locations where it is necessary to move packages and other items in and out of trucks and shipping containers.Extendable, telescoping conveyors can improve productivity and efficiency at the dock door.

-

Super Lowest Price China Gravity Telescopic Flexible Expandable Roller Conveyor for Industry

Roller conveyors are a form of conveyor belt that utilizes rollers – evenly-spaced rotating cylinders – to allow objects to skate across its surface. They move material from one place to another destination, and often leverage gravity or implement small motors to do so.

-

Wholesale Price China China 2022 Factory High Efficiency Feed Equipment Sand Mud Sludge Grain Special Conveyer Winch Screw Conveyor for Sale

A screw conveyor or auger conveyor is a mechanism that uses a rotating helical screw blade, called a “flighting”, usually within a tube, to move liquid or granular materials. They are used in many bulk-handling industries. Screw conveyors in modern industry are often used horizontally or at a slight incline as an efficient way to move semi-solid materials, including food waste, wood chips, aggregates, cereal grains, animal feed, boiler ash, meat, and bone meal, municipal solid waste, and many others.

-

ODM Factory China Stainless Steel Auger Spiral Cement Conveyor Factory Screw Conveyor

Turning belt Conveyor is a kind of conveyors of belt conveyors ,belt conveyors are most commonly used in transportation of bulk materials (grain, salt, coal, ore, sand, etc.). Belt conveyor systems consist of two or more pulleys. An endless loop of carrying medium—the conveyor belt— rotates about them.

-

Factory wholesale China 2021 Plastic Flexible Chain Spiral Conveyor for Small Bags Transportation for Tea Factory or Tobacco Factory

Roller conveyors are a form of conveyor belt that utilizes rollers – evenly-spaced rotating cylinders – to allow objects to skate across its surface. They move material from one place to another destination, and often leverage gravity or implement small motors to do so.

-

Factory supplied China Jiutong Galvanized or PU / Rubber Coated Lathing Roller for Belt Conveyor, Drive Roller

Roller conveyors are a form of conveyor belt that utilizes rollers – evenly-spaced rotating cylinders – to allow objects to skate across its surface. They move material from one place to another destination, and often leverage gravity or implement small motors to do so.

-

Top Quality China Gravity Roller Conveyor in Conveyor System

The non-gravity double-shaft paddle mixer has the characteristics of strong, high efficiency, short mixing time, design mixing time of 1-3 minutes, 1:1000 distribution ratio uniformity is greater than 95%, the two mixing shafts in the horizontal cylinder rotate in opposite directions at the same speed , The blades arranged at a special angle on the shaft ensure that the material is sprayed in the radial, circumferential and axial directions at the same time, forming a compound compound cycle, and achieving uniform mixing in a short time.

-

OEM Supply China Powder Conveying Machine Spiral Screw Conveyor (Ls160)

Horizontal spiral ribbon mixer is composed of spiral ribbon rotating parts;

The outer spiral gathers materials from both sides to the center,

The inner spiral conveys materials from the center to both sides to form convective mixing. The spiral ribbon mixer has a good effect on the mixing of viscous or cohesive powders and granules.

-

Special Design for China Belt Conveyor Steel Trough Roller Carrier Roller Carrying Roller Trough Idler Roller Carrier Idler Carrying Idler Conveyor Roller

Filling weight::1-500g

Dosing way :auger filling

Hopper volume : 50L

Package accuracy :≤±0.3-1%

Package speed :10-55 times/ minute

Power supply:380v 50-60hz /1.7kw

Dimensions:800X1200X2150mm

Include control system: touch screen, PLC and electrical box

MX-1B3 Semi-automatic Auger filing machine is semi-automatic equipment, air damping combined transparent material box, recyclable dust suction device lifting table, suitable for packaging powdered materials, such as milk powder, feed, rice flour, sugar, monosodium glutamate, solid beverages, glucose, solid medicine

-

Bottom price China Acrylic Coated Coating Fiberglass Fire Retardant Fabric Anti-Fire Fabric High Silica Fabric Heat Resistant Abrasion Resistance Fiberglass Cloth

Electric wheels sorting machine conveyor used in logistic dividing bag,wheels sorting machine is an equipment used for belt conveyor system or roller conveyor system. The characteristics of this design is to track conveyed goods accurately and stably as well as set sorting positions at any position along both sides of conveyor lines conveniently to satisfy customers with different sorting requirements.

-

Leading Manufacturer for China IKO K45X60X40 Radial Needle Roller and Cage Assemblies K19*23*17, K20*24*17 Bearing

A screw conveyor or auger conveyor is a mechanism that uses a rotating helical screw blade, called a “flighting”, usually within a tube, to move liquid or granular materials. They are used in many bulk-handling industries. Screw conveyors in modern industry are often used horizontally or at a slight incline as an efficient way to move semi-solid materials, including food waste, wood chips, aggregates, cereal grains, animal feed, boiler ash, meat, and bone meal, municipal solid waste, and many others.

-

Wholesale OEM China Gravity Flexible Roller Conveyor

MUXIANG Floating garbage collector equipment, the main function is to capture floating garbage, separate floating garbage and sewage, and automatically put garbage on shore for bucketing. The principle is to use the high-flow suction formed by the swirling device to force the floating garbage to gather in the direction of the collection bucket. The filter screens of the inner and outer barrels are used to separate the garbage and the water and capture the garbage. The electric lift is used to automatically send the garbage to the top of the pool and automatically dump it into the garbage can, thereby completing the collection of floating garbage.

Advanced technology, leading technology, efficient capture, ensuring compliance

Automatic control, energy saving and noise reduction, simple management, convenient operation and maintenance

High quality, controllable area, low cost, and thoughtful after-sales.

-

Factory Customized China High Quality Automatic Belt Conveyor

Turning belt Conveyor is a kind of conveyors of belt conveyors ,belt conveyors are most commonly used in transportation of bulk materials (grain, salt, coal, ore, sand, etc.). Belt conveyor systems consist of two or more pulleys. An endless loop of carrying medium—the conveyor belt— rotates about them.

-

Cheapest Price China Long Life Heavy Duty Steel Carrier Dustproof Gravity Belt Conveyor Idler Roller for Coal Mining Trough Idler Steel Roller with Frame for Belt Conveyor

Electric wheels sorting machine conveyor used in logistic dividing bag,wheels sorting machine is an equipment used for belt conveyor system or roller conveyor system. The characteristics of this design is to track conveyed goods accurately and stably as well as set sorting positions at any position along both sides of conveyor lines conveniently to satisfy customers with different sorting requirements.

-

Cheap price China Belt Conveyor Steel Screw Roller with High Quality for Exporting

Roller conveyors are a form of conveyor belt that utilizes rollers – evenly-spaced rotating cylinders – to allow objects to skate across its surface. They move material from one place to another destination, and often leverage gravity or implement small motors to do so.

-

2019 Good Quality China Steel Spiral Tensioning Device/Conveyro Accessris/Steel Roller/Conveyor Coller

A screw conveyor or auger conveyor is a mechanism that uses a rotating helical screw blade, called a “flighting”, usually within a tube, to move liquid or granular materials. They are used in many bulk-handling industries. Screw conveyors in modern industry are often used horizontally or at a slight incline as an efficient way to move semi-solid materials, including food waste, wood chips, aggregates, cereal grains, animal feed, boiler ash, meat, and bone meal, municipal solid waste, and many others.

-

Manufactur standard China Self-Adjusting Roller Conveyor Roller Steel Roller with Bracket for Belt Conveyor

Roller conveyors are a form of conveyor belt that utilizes rollers – evenly-spaced rotating cylinders – to allow objects to skate across its surface. They move material from one place to another destination, and often leverage gravity or implement small motors to do so.

-

Quality Inspection for China High Effeciency Vertical Spiral Roller Conveyor Elevator Supplier for Pet Bottles Jars

Electric wheels sorting machine conveyor used in logistic dividing bag,wheels sorting machine is an equipment used for belt conveyor system or roller conveyor system. The characteristics of this design is to track conveyed goods accurately and stably as well as set sorting positions at any position along both sides of conveyor lines conveniently to satisfy customers with different sorting requirements.

-

Factory source China Conveyor Belt Spiral Gravity Roller Conveyor High Quality Cooling Tower Conveyor

Turning belt Conveyor is a kind of conveyors of belt conveyors ,belt conveyors are most commonly used in transportation of bulk materials (grain, salt, coal, ore, sand, etc.). Belt conveyor systems consist of two or more pulleys. An endless loop of carrying medium—the conveyor belt— rotates about them.

-

Professional China China Material Handling Equipment Portable PVC Roller Conveyor for Bags Carton Box

Telescopic conveyer suitable for bulk Bags loading and unloading from the trucks. A telescoping conveyor is a flat conveyor that operates on telescopic slider beds. They are popular at receiving and shipping docks where the conveyor is extended into inbound or outbound trailers for unloading or loading. These conveyors used for loading of boxes and cartons in trucks and containers.

-

8 Years Exporter China Suction Press Roller, Wire Drive Roller, Blind Roller for Paper Machine

The Extendable Belt Conveyor is a telescoping conveyor that extends into the truck trailer as an ergonomic solution for loading and unloading. These conveyors are most commonly found in shipping and receiving areas, warehouses, and other locations where it is necessary to move packages and other items in and out of trucks and shipping containers.Extendable, telescoping conveyors can improve productivity and efficiency at the dock door.

-

Professional Factory for China Hot Sale Stainless Steel Screw Feeder Conveyor (Ls160)

Electric wheels sorting machine conveyor used in logistic dividing bag,wheels sorting machine is an equipment used for belt conveyor system or roller conveyor system. The characteristics of this design is to track conveyed goods accurately and stably as well as set sorting positions at any position along both sides of conveyor lines conveniently to satisfy customers with different sorting requirements.

-

Excellent quality China Customized PVC Belt Conveyor for Packing

Turning belt Conveyor is a kind of conveyors of belt conveyors ,belt conveyors are most commonly used in transportation of bulk materials (grain, salt, coal, ore, sand, etc.). Belt conveyor systems consist of two or more pulleys. An endless loop of carrying medium—the conveyor belt— rotates about them.

-

New Fashion Design for China Speed Adjustable Small Spiral Gravity Conveyor Spiral Mesh Conveyor Belt Spiral Conveyor for Cooling

Roller conveyors are a form of conveyor belt that utilizes rollers – evenly-spaced rotating cylinders – to allow objects to skate across its surface. They move material from one place to another destination, and often leverage gravity or implement small motors to do so.

-

Wholesale ODM China Professional Custom Food Grade Stainless Steel Spiral Mesh Conveyor Belt Metal Wire Mesh Conveyor Belt

Belt conveyors are most commonly used in transportation of bulk materials (grain, salt, coal, ore, sand, etc.). Belt conveyor systems consist of two or more pulleys. An endless loop of carrying medium—the conveyor belt— rotates about them.

-

Factory Price For China Customized Roller Conveyor for Packing

Telescopic conveyer suitable for bulk Bags loading and unloading from the trucks. A telescoping conveyor is a flat conveyor that operates on telescopic slider beds. They are popular at receiving and shipping docks where the conveyor is extended into inbound or outbound trailers for unloading or loading. These conveyors used for loading of boxes and cartons in trucks and containers.

-

Bottom price China Fully Automatic Gravity Spiral Roller Conveyor for Bread Processing

MUXIANG Floating garbage collector equipment, the main function is to capture floating garbage, separate floating garbage and sewage, and automatically put garbage on shore for bucketing. The principle is to use the high-flow suction formed by the swirling device to force the floating garbage to gather in the direction of the collection bucket. The filter screens of the inner and outer barrels are used to separate the garbage and the water and capture the garbage. The electric lift is used to automatically send the garbage to the top of the pool and automatically dump it into the garbage can, thereby completing the collection of floating garbage.

Advanced technology, leading technology, efficient capture, ensuring compliance

Automatic control, energy saving and noise reduction, simple management, convenient operation and maintenance

High quality, controllable area, low cost, and thoughtful after-sales.

-

Original Factory China Gravity or Powered Spiral Screw Vertical Conveyor Big Box Upload System

Electric wheels sorting machine conveyor used in logistic dividing bag,wheels sorting machine is an equipment used for belt conveyor system or roller conveyor system. The characteristics of this design is to track conveyed goods accurately and stably as well as set sorting positions at any position along both sides of conveyor lines conveniently to satisfy customers with different sorting requirements.

-

Wholesale Price China China Factory Price Gravity Turning Conveyor Stainless Steel Roller Table Conveyor

Turning belt Conveyor is a kind of conveyors of belt conveyors ,belt conveyors are most commonly used in transportation of bulk materials (grain, salt, coal, ore, sand, etc.). Belt conveyor systems consist of two or more pulleys. An endless loop of carrying medium—the conveyor belt— rotates about them.

-

Wholesale Price China China Conveyor Belt Spiral Gravity Roller Conveyor High Quality Cooling Tower Conveyor

Telescopic conveyer suitable for bulk Bags loading and unloading from the trucks. A telescoping conveyor is a flat conveyor that operates on telescopic slider beds. They are popular at receiving and shipping docks where the conveyor is extended into inbound or outbound trailers for unloading or loading. These conveyors used for loading of boxes and cartons in trucks and containers.

-

Super Lowest Price China ABS Wheel Telescopic Roller Conveyor Belt Flexible Expansion Ratio 3: 1

The Extendable Belt Conveyor is a telescoping conveyor that extends into the truck trailer as an ergonomic solution for loading and unloading. These conveyors are most commonly found in shipping and receiving areas, warehouses, and other locations where it is necessary to move packages and other items in and out of trucks and shipping containers.Extendable, telescoping conveyors can improve productivity and efficiency at the dock door.

-

Manufacturing Companies for China Return/Flat Return Rollers Are Used to Support The Belt to Prevent Stretching and Sagging

Roller conveyors are a form of conveyor belt that utilizes rollers – evenly-spaced rotating cylinders – to allow objects to skate across its surface. They move material from one place to another destination, and often leverage gravity or implement small motors to do so.

-

Short Lead Time for China Horizontal Belt Conveyor with Adjustable Height for Shoes

Telescopic conveyer suitable for bulk Bags loading and unloading from the trucks. A telescoping conveyor is a flat conveyor that operates on telescopic slider beds. They are popular at receiving and shipping docks where the conveyor is extended into inbound or outbound trailers for unloading or loading. These conveyors used for loading of boxes and cartons in trucks and containers.

-

Personlized Products China Factory Unpowered Folding Flexible Gravity Telescopic Mobile Belt Roller Conveyor

Roller conveyors are a form of conveyor belt that utilizes rollers – evenly-spaced rotating cylinders – to allow objects to skate across its surface. They move material from one place to another destination, and often leverage gravity or implement small motors to do so.

-

Well-designed China Flexible and Retractable Gravity Carbon Steel Roller Conveyor for Industrial Warehouses

Telescopic conveyer suitable for bulk Bags loading and unloading from the trucks. A telescoping conveyor is a flat conveyor that operates on telescopic slider beds. They are popular at receiving and shipping docks where the conveyor is extended into inbound or outbound trailers for unloading or loading. These conveyors used for loading of boxes and cartons in trucks and containers.

-

China Factory for China Garlic Peeling Machine After Breaking or Seperating Process

MUXIANG Floating garbage collector equipment, the main function is to capture floating garbage, separate floating garbage and sewage, and automatically put garbage on shore for bucketing. The principle is to use the high-flow suction formed by the swirling device to force the floating garbage to gather in the direction of the collection bucket. The filter screens of the inner and outer barrels are used to separate the garbage and the water and capture the garbage. The electric lift is used to automatically send the garbage to the top of the pool and automatically dump it into the garbage can, thereby completing the collection of floating garbage.

Advanced technology, leading technology, efficient capture, ensuring compliance

Automatic control, energy saving and noise reduction, simple management, convenient operation and maintenance

High quality, controllable area, low cost, and thoughtful after-sales.

-

ODM Factory China Dust Proof Swivel Oblique Guide Wheel Sorter Parel

MUXIANG Floating garbage collector equipment, the main function is to capture floating garbage, separate floating garbage and sewage, and automatically put garbage on shore for bucketing. The principle is to use the high-flow suction formed by the swirling device to force the floating garbage to gather in the direction of the collection bucket. The filter screens of the inner and outer barrels are used to separate the garbage and the water and capture the garbage. The electric lift is used to automatically send the garbage to the top of the pool and automatically dump it into the garbage can, thereby completing the collection of floating garbage.

Advanced technology, leading technology, efficient capture, ensuring compliance

Automatic control, energy saving and noise reduction, simple management, convenient operation and maintenance

High quality, controllable area, low cost, and thoughtful after-sales.

-

2019 China New Design China Technological Computer PLC Control ABS Refrigerator Plate Production Line

MUXIANG Floating garbage collector equipment, the main function is to capture floating garbage, separate floating garbage and sewage, and automatically put garbage on shore for bucketing. The principle is to use the high-flow suction formed by the swirling device to force the floating garbage to gather in the direction of the collection bucket. The filter screens of the inner and outer barrels are used to separate the garbage and the water and capture the garbage. The electric lift is used to automatically send the garbage to the top of the pool and automatically dump it into the garbage can, thereby completing the collection of floating garbage.

Advanced technology, leading technology, efficient capture, ensuring compliance

Automatic control, energy saving and noise reduction, simple management, convenient operation and maintenance

High quality, controllable area, low cost, and thoughtful after-sales.

-

High reputation China Jare A9 Luxury SL Track Full Body Airbags Multifunction Zero Gravity Recliner Massage Chair

MUXIANG Floating garbage collector equipment, the main function is to capture floating garbage, separate floating garbage and sewage, and automatically put garbage on shore for bucketing. The principle is to use the high-flow suction formed by the swirling device to force the floating garbage to gather in the direction of the collection bucket. The filter screens of the inner and outer barrels are used to separate the garbage and the water and capture the garbage. The electric lift is used to automatically send the garbage to the top of the pool and automatically dump it into the garbage can, thereby completing the collection of floating garbage.

Advanced technology, leading technology, efficient capture, ensuring compliance

Automatic control, energy saving and noise reduction, simple management, convenient operation and maintenance

High quality, controllable area, low cost, and thoughtful after-sales.

-

OEM Supply China Ne200 Chain Board Type Bucket Elevator

MUXIANG Floating garbage collector equipment, the main function is to capture floating garbage, separate floating garbage and sewage, and automatically put garbage on shore for bucketing. The principle is to use the high-flow suction formed by the swirling device to force the floating garbage to gather in the direction of the collection bucket. The filter screens of the inner and outer barrels are used to separate the garbage and the water and capture the garbage. The electric lift is used to automatically send the garbage to the top of the pool and automatically dump it into the garbage can, thereby completing the collection of floating garbage.

Advanced technology, leading technology, efficient capture, ensuring compliance

Automatic control, energy saving and noise reduction, simple management, convenient operation and maintenance

High quality, controllable area, low cost, and thoughtful after-sales.