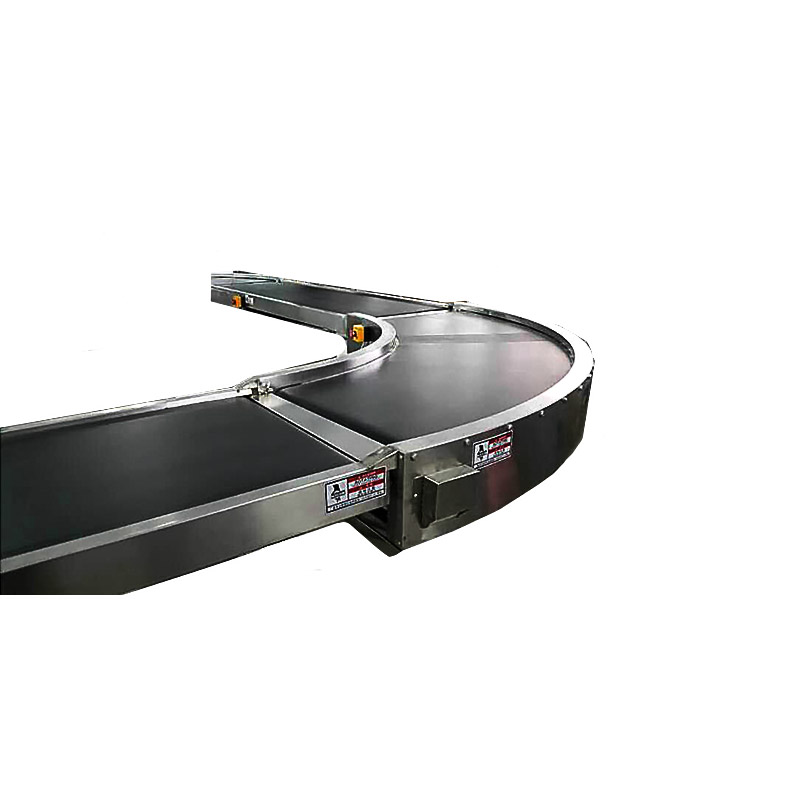

A conveyor system systematically carries and transports materials, typically in an industrial or controlled environment. Conveyor belts are a tried-and-true energy saver designed to increase efficiency. Let’s take a look at how conveyor belts work and why they’ve stood the test of time.

How a Conveyor Belt Works?

A conveyor belt works by using two motorized pulleys that loop over a long stretch of thick, durable material. When motors in the pulleys operate at the same speed and spin in the same direction, the belt moves between the two.

If objects are particularly heavy or bulky — or if the conveyor belt is carrying them for a long distance or duration — rollers may be placed on the sides of the conveyor belt for support.

Parts of the Conveyor Belt System

While there are numerous types of conveyor systems, all serve the same purpose of transporting materials. Some products may require a system without a belt, using only rollers or wheels for flexible movement. However, many conveyor systems rely on a frame with a belt and possible support rollers to carry materials and products efficiently.

All conveyor systems have three main components — the aluminum profile, the driving unit and the extremity unit.

In a conveyor belt system, the aluminum profile consists of the frame, belt and any supports. Systems that use a belt are generally powered by a motor, though conveyor systems can also use gravity or manual force to function. Motorized conveyor belts are ideal for industrial use as they are more reliable and efficient — the driving unit for such systems would include the motor bracket, electrical drive and any counter bearings.

The conveyor belt system’s extremity unit typically includes any pulleys and clamping straps. Additional stands or lateral guides could be necessary for specific variations or functions, so consider your industry’s needs when choosing these optional add-ons. Parts and functions of a new conveyor belt system might include:

● The frame: The system’s framework holds all of the moving parts together for safe and secure operation.

● The belt: A long stretch of thick, durable material upon which materials are transported from one place to another.

● The conveyor belt support: Rollers assist the belt to stay on course and swiftly maintain movement. Rollers keep objects in place and prevent the belt from sagging.

● The driving unit: Motors may use either variable or constant speed-reduction gears to power the conveyor belt. An efficient driving unit must continually assist the belt with continuous running, smooth reversing and repeatedly adjusting direction.

● The pulleys: The conveyor belt should loop over two or more strategically positioned pulleys. The pulley controls the belt’s movement and performs critical functions such as driving, redirecting, turning, tensioning and tracking the belt.

● The clamping straps: Clamping straps are used on various machines to hold down fixtures and work components.

● Add-on modules: Most additional parts are installed for further reinforcement. While rollers support the belt from within the system, stands and lateral guides support the outer framework.

Conveyor belting can be crafted from various materials, including rubber, metal, leather, fabric and plastic. Consider the conditions that your system will operate under to ensure the conveyor belting material is of suitable thickness and strength.

Post time: Mar-07-2023