High reputation Masala Powder Packing Machine - pneumatic mixer – Muxiang

High reputation Masala Powder Packing Machine - pneumatic mixer – Muxiang Detail:

pneumatic mixer is a three-in-one equipment integrating suction, mixing and sending functions. The whole machine is made of stainless steel, which is especially suitable for GMP certification, food hygiene certification, and mixing and conveying of products that require anti-corrosion chemical products.

The BHQ series pneumatic mixer is a PLC touch screen interface, which has the advantages of stable work, anti-interference, convenient and intuitive operation, and the control parameters of each stage can be freely changed.

The BHQ series pneumatic mixer has two feeding methods to choose from. The direction of the inlet and outlet can be changed freely. The ear seat can be equipped with 3 load cells for material weighing, which can meet the mixing of powder and small particles. , The mixing process is gentle and will not destroy the original state of the material; the mixing efficiency is high. The exhaust port of the machine is bent downward to reduce the impact of exhaust on the roof.

The entire equipment of the BHQ series pneumatic mixer has a simple structure and is easy to maintain. All working accessories are standard parts, which are convenient for purchase and replacement.

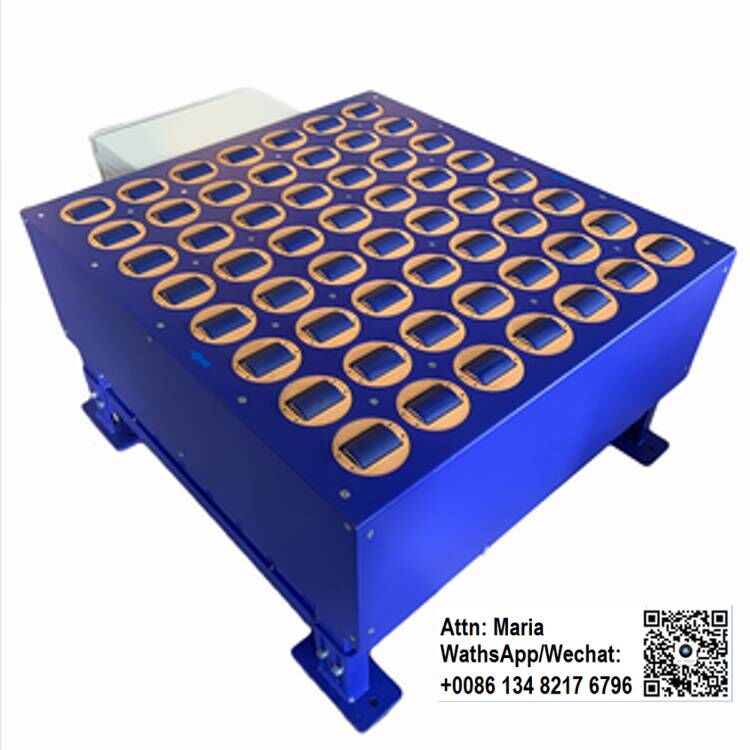

Product detail pictures:

Related Product Guide:

With dependable high-quality method, fantastic standing and ideal purchaser assistance, the series of products produced by our firm are exported to many countries and regions for High reputation Masala Powder Packing Machine - pneumatic mixer – Muxiang , The product will supply to all over the world, such as: South Africa, Iran, Mexico, We are looking forward to establishing a mutually beneficial relationship with you based on our high-quality products, reasonable prices and best service. We hope that our products will bring you a pleasant experience and carry a feeling of beauty.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!